Acrylic window | Mounting features | EMI shielding | Painting and coating | Part marking

Acrylic window

Bonded in the enclosure, the clear window "see through" will protect your display.

Material:

- Clear Acrylic in 2 or 3mm

Comments:

- Dimensions and positioning are custom

- The window is bonded in the enclosure flush to the top surface

- Other options are possible to make the clear window removable

- Screw fixings from inside

- Snap-in, in this case, the window is proud of the surface

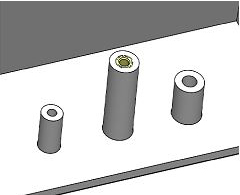

Mounting features

Our enclosures include all the mounting features to accomodate your electronic parts:

Insert:

- Directly in the plastic, or inserted in a standoff, our inserts will allow you to screw your circuit board in the case :

- Material: Brass

- Screws: M3 or M4

- Custom made and positionned

Standoff :

- Bonded on the bottom / walls / sides or top. they allow you to mount your electronic parts:

- They come with threaded inserts

- Available heights: from 2 to 20mm

- Material: HIPS

- Position "on demand"

Tabs / Rails / Blocks:

- Custom designed depending on your needs, they will locate / limit / stop any electronic parts.

- With our without inserting, they have the same function as standoffs, with more bonding surface and better resistance and reinforcement:

- Dimensions custom entirely

- Position "on demand"

- Material : HIPS

Loose parts:

- Essentially used for setting limits or obturate

EMI shielding

In order to insure conductivity across the enclosure, we spray Copper Shielding. We can either spray prior to machining or after assembly, depending on your needs.

What we use:

- Copper Shielding

Comments:

- Our EMI vendor is known all over the world. Specifications available upon request.

EMI Advice:

- Our technical staff will help you choose the best design option for your enclosure.

- Protect from UV light and keep the plastic from turning yellow over time; especially Flame Retardant plastic.

- Cover scratches and milling lines that could occur during our machining process.

- Obtain custom colours, improving cosmetic finish, and matching perfectly your colour logo, or your customer's logo.

These operations are made in-house at no extra costs, or no extra time (for 1 color).

Available colors:

- Any European RAL

- Pantone upon request

Clear coating:

- Coating is integrated in our colour paint

- It can also be sprayed by itself, with no colour paint

- For intense protection, we also have super resistant coating upon request.

Part marking

Part Marking is essential to indentify some features, your company logo, the device ... This process is made in house and at very limited cost. Take advantage of it now:

Engraving:

- Milled in the material with a depth of 0,5 mm and diameter of 0,3 mm.

Silkscreen:

- Pick your colors, fully integrated. Though, this process adds to our standard delivery time.

- Acrylic ink with solvant or UV-ink.

- Contact our staff for delivery time.

Label:

- Vinyl or polycarbonate, thickness of 0,3 mm, placed in a recess.